It has been described as the biggest lung disease crisis since asbestos. And if you work with concrete, bricks, tiles, sandstone or granite, it’s crucial to be aware of the serious dangers of silica dust and its potential consequences, including the irreversible lung disease silicosis. Kathryn Kernohan reports.

The dangers of silica dust have been known since the early 1700s, when Italian physician Bernardino Ramazzini discussed the asthma-like symptoms observed in stonecutters.

However, the potentially fatal dangers have become more understood in recent decades.

In the US, The Centers for Disease Control (CDC) calculates that there have been more than 2,000 fatal cases of silicosis since the start of the 21st century.

Closer to home, the Cancer Council says that close to 600,000 Australian workers including stonemasons, plumbers, construction workers, miners and engineers were exposed to silica dust in the workplace in 2011. They estimate that a staggering 5,758 of these people will develop a lung disease during their life.

Stonemasons are one of the professions most at risk as shown by some alarming local statistics. More than 100 stonemasons in Queensland were diagnosed with silicosis in a recent six month period, and in Victoria, 35 stonemasons lodged claims with WorkSafe Victoria between July 2017 and March 2019.

“While plumbing is not at the top of the at-risk register, every plumber needs to be vigilant and protect themselves and educate their staff,” Master Plumbers CEO Peter Daly said.

“Knowing the risks means we can do something to stop it becoming the next silent killer, the next asbestos.”

What is silica?

Crystallina Silica is a naturally occurring mineral common in rocks and rock products. It is most prevalent in reconstituted stone, where it comprises more than 80% of the material. Many reported cases of silicosis in Australia have been of workers who work with engineered stone products such as kitchen benchtops.

Silica also comprises up to 45% of tile and 15% of brick.

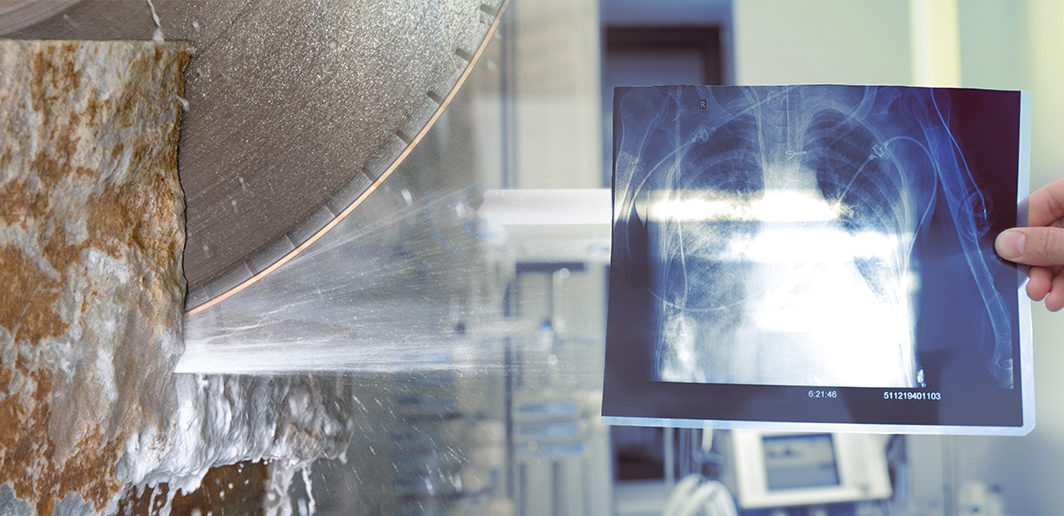

When materials such as composite stone, granite or sandstone are crushed, drilled, cut, sawed or polished, they generate silica dust. These particles are often so small they are not visible, but can embed themselves deep within the lungs regardless of whether there has been high exposure over short periods of time or low exposure over longer periods.

What are the risks?

Like exposure to other dust materials, silica dust can initially cause irritation of the eyes, nose and throat. Over time, some of the more serious risks include lung cancer, kidney disease, chronic obstructive pulmonary disease and silicosis.

Silicosis is a potentially fatal and irreversible scarring and stiffening of the lungs with no cure. It occurs in three forms. The most common is chronic silicosis, closely linked with respiratory problems and developed from long-term exposure to low quantities of silica dust.

Acute silicosis results from short-term exposure to large amounts of silica dust and is linked with low blood oxygen levels, and accelerated silicosis leads to swelling in the lungs at a faster speed.

What is being done?

Fortunately, as more is being learned about the dangers of silicosis, leaders across the country are pledging action.

Before the Federal Government was re-elected in May, it committed $5 million to establish a national dust diseases taskforce.

The taskforce will bring together medical professionals, researchers and industry figures to develop a national strategy for preventing dust diseases, including silicosis, as well as strategies around early detection methods and effective treatments.

In Victoria, the State Government has announced a range of initiatives headlined by a statewide ban on uncontrolled dry cutting of materials that contain crystalline silica dust. Free health screenings for stonemasons and a new compliance code for businesses that work with silica are other measures to improve health and safety for workers.

Dry cutting of engineering stone is already banned in Queensland, and organisations such as the Royal Australasian College of Physicians continue to advocate for the ban to be extended nationwide.

There is also action in the court rooms, with law firm Slater and Gordon recently announcing plans for a class action against several manufacturers of constituted stone products, claiming they failed to adequately warn workers about dangers. The firm is representing a number of stonemasons across Australia in the action.

How can you protect yourself?

Implementing strategies to minimize exposure to silica dust in the first place is the best way to avoid danger.

These can range from substituting materials that will produce silica dust with safer materials, through to ordering only the required size of materials to lessen the need for cutting.

“In scenarios where working with materials that produce silica dust is unavoidable, it is important to employ wet cutting methods on materials like brick, tile, concrete and stone,” Mr Daly said.

A 2013 controlled study found that wet cutting reduced respirable dust concentration by 85% compared to dry cutting.

“Additionally, dust extraction devices can be used with a variety of handheld tools to remove dust as it is being produced.”

“Workers who may be exposed to silica dust on a regular basis can further prevent exposure to silica dust by utilising respiratory protective equipment and, where possible, wearing disposable clothing at work to avoid bringing hazards home.”

To stay up to date with the latest research visit the relevant state authority website or Safe Work Australia.

Share this Article