Victoria is the only state in Australia that has regulated residential roofing; allowing only qualified and appropriately licensed roofing plumbers to undertake work. Gary Bath reports.

Victoria remains the only jurisdiction in Australia that calls up both HB-39 Code of Practice for the Installation of Metal roofing and Cladding and HB114 guidelines for the design of Eaves and Box Gutters in legislation.

In the most recent Victorian Building Authority (VBA) report on inspections for 2021/2022, which focusses on inspections of buildings under construction both commercial and residential, roofing non-compliance remains at the top. Additionally, roofing issues rate the highest in terms of complaints and insurance claims of any other plumbing work.

So why the large failure rate and why is it so hard to comply?

Certainly, changes to residential building design that now encompass internal valley, lear and in some cases box gutters contribute to the problem. Sometimes installations have been provided with inadequate or no means for overflow should a blockage occur. Another aspect is the certification process for the residential constructions. These so called “certified plans” provided to the builder via the Building Surveyor are often passed on to the roof plumber. The plans, whilst “certified” for construction seldom have a roof-drainage design that would meet the existing deemed to satisfy (DTS) requirements of AS/NZS3500.3. Particularly where there are internal gutters, which may have downpipe locations, sizes and even sumps noted, seldom have these been calculated by anyone to meet the Australian Standard. Some Roof Plumbers wrongly assume that these drawings can be used for their completed installation. The nature of the self-certification regime in Victoria also means that the installing plumber who lodges the Compliance Certificate for this roof also takes responsibility for the design.

But more on that later…

Often, there is confusion about how to ensure that existing roof-drainage systems can be made to conform to the current AS/NZS3500.3 requirements during renovations. These broadly fall into the following categories:

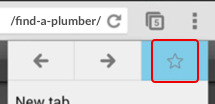

- A “V gutter”- usually found between intersecting roofs or where a roof abuts a parapet. These are not box gutters, can not be sized and are difficult to maintain. A replacement of something like this would need to utilise a more traditional box-gutter design. See diagram

- Concealed gutter - was widely used through the 70s/80s instead of exposed-eaves gutters that sit outside the building’s eaves. The concealed gutter sits within the eave. Existing installations can be replaced if adequate overflow protection can be incorporated in which case these can be installed to meet the existing DTS provisions of the Standard. See diagram

- Box gutter with a lear - most commonly found where a roof abuts a parapet wall. Again these can be sized and installed to meet the DTS requirements of the Standard. See diagrams 3 and 4.

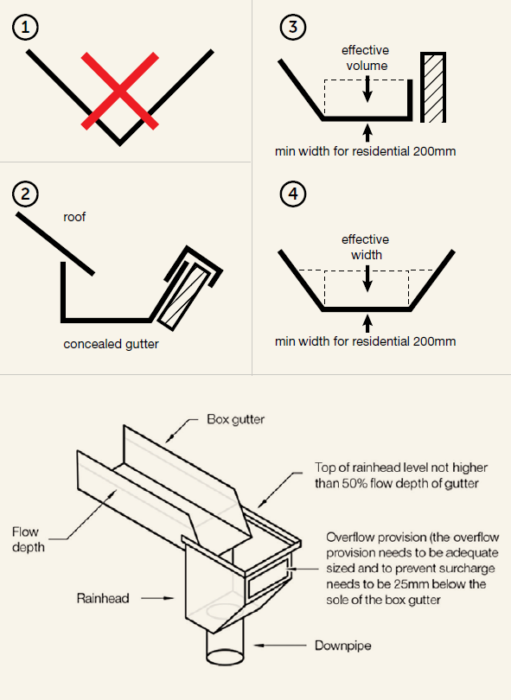

- Box gutter - important to remember that the minimum size for a residential building is 200mm wide. Minimum depth must be developed by calculating the specific rainfall intensity for that roof. Many refer to the HB-39 definition for box gutters, which refers to a minimum depth of 75mm, this is often found to be too shallow when the gutter is sized according to the tables in AS/NZS3500.3. Box gutters must have overflow protection either through the installation of a rainhead, sump with side overflow or sump with high-capacity overflow. Most common issues arise when a box gutter might be required to capture an intersecting roof or in fact go around a corner. These can still be designed to meet DTS of the Standard but will often require some lateral thinking along where to place sumps, etc.

Another important consideration is the overflow, which prevents water entering the building as a result of a blockage in either the stormwater system or the downpipe.

Often the roof plumber is faced with a constructed building and now has to design a roof drainage system to comply! Roof concealed gutter effective.

All gutters require on-going maintenance. Box gutters, require more regular maintenance due to sumps or rainheads having a tendency to become blocked by rubbish, leaves, sporting equipment, etc.

Changes to HB39

Recent changes to the Roofing and Walling Code of Practice, largely at the request of the Victorian Building Authority and without any discussion with stakeholders, has focused the issue of a “deemed to comply” rainhead. These changes now mean that a rainhead, in the view of the VBA, must have an overflow provision that is located 25mm below the bottom of the box gutter that runs into it and importantly, must be fully open above that weir. This has caused some issues within the industry as it now means that the box gutter is open to view and depending on the geography of the surrounding landscape, the property owner isn’t always that pleased with the end result.

Performance solutions

Often when faced with an installation that may not, on the face of it, meet the DTS requirements of the AS/NZS3500 Standard roof plumbers are most concerned about meeting the requirements of the Performance Solution. Most commonly, when we choose to use slotted eaves gutter in lieu of the DTS for providing a physical means of overflow we are in fact utilising a Performance Solution. Firstly, a Performance Solution should be identified prior to construction as the owners/ agents of the owners will need to agree to this outcome. Secondly, you will need to provide the necessary evidence that what you plan to install will meet or exceed the minimum requirements of the DTS solution in the Standard. Often plumbers will engage external people such as those that specialise in developing such outcomes, eg hydraulic engineers, etc. More often there are others such as manufacturers who might provide the necessary calculations or evidence. One such manufacturer is Dambuster, who have developed a rainhead/sump system that not only meets the DTS outcomes for a standard installation but often can be used on installations that are more complex or require a performance solution. Dambuster also provide access to a very simple sizing chart that will allow the plumber to calculate and order the installation material as required, even in situations that may require a change of direction in the gutter.

Checklist for installing internal gutters or box gutters:

- Don’t assume that because the plan is stamped that anyone with any knowledge or qualifications has designed the internal gutter system. Size and location of gutter, sumps, etc should be checked to see if they firstly comply with the DTS or treated as a Performance Solution.

- Regardless of what the developer, architect, building contractor say, ultimately it is your compliance issue for the design and the installation of the system

- A well thought-out performance solution is a compliant alternative.

- There is help and assistance out there should you require it.

Share this Article