Hydrogen is hitting homes and business including, most recently, the crematoria sector. Kathryn Kernohan delves into the latest industry to take a step toward a cleaner future.

Australia has an ambitious goal to become a major- global player in the hydrogen industry in the next decade - in line with the Federal Government’s commitment to reduce greenhouse gas emissions to 43 per cent below 2005 levels by the end of the decade.

Hydrogen is now being blended with natural gas to supply homes and businesses and is helping to power cars, trucks and even barbecues around the country.

And if Geelong’s boutique engineering firm Austeng has its way, hydrogen may also completely revolutionise the crematoria sector in years to come.

“The much talked about promise of green hydrogen is harnessing the power of electricity generated from renewables to split water atoms to capture hydrogen that can power heavy industry with a zero emissions fuel. Hundreds of millions of dollars have already been spent in Australia alone to

develop the industry,” explains Ross George, Managing Director of Austeng.

“Fuels producing high flame temperatures such as hydrogen are well suited for cremation whether retro fitted to existing equipment or purpose built. By adapting cremation systems to utilise clean renewable fuels, there is an opportunity to create a sustainable means of departure for humankind.”

Research conducted in South Australia in 2008 found that 160 kilograms of carbon dioxide is produced on the day of a cremation. Ross says that current estimates indicate that there are more than 32,000 cremations conducted in Victoria each year.

L-R Ella George (Member for Lara), Minister Lily D’Ambrosio (Minister for Energy and Resources), Ross George (AUSTENG)

Austeng has calculated that natural gas fired cremators, contribute to 1594 tonnes of Victoria’s CO2 emissions per year. If 35 per cent of the energy required per cremation were to be from green hydrogen, as hydrogen doesn’t create any CO2 when combusted, this would see an annual reduction of CO2 emissions in Victoria alone of 556 tonnes.

Austeng has a reputation as Australia’s leading supplier of engineering services to the cemetery and crematoria industries, manufacturing as well as servicing high-standard cremators and associated equipment such as cremovacs and automated charge biers.

Having already explored the promotion of environmental sustainability outcomes including geopolymer as an alternative to concrete and alkaline hydrolysis process “water cremators,” investigating a hydrogen fueled cremator seemed like a logical next step.

L-R Tim Cleary and Ross George (AUSTENG) and Minister Lily D’Ambrosio

Thanks to a grant from the Victorian Government’s Renewable Hydrogen Business Ready Fund, established to enable businesses to identify pathways to transition to renewable hydrogen, that’s exactly what Austeng has done over the past two years.

“It took us about 18 months to do background research on industry requirements and then to design, manufacture, install and commission the hydrogen burner, which necessitated working closely with Energy Safe Victoria to identify and comply with regulatory requirements,” says Ross.

“Consents were obtained for the complex pipework medication to existing gas burner, also a key step was the establishment of operational and safety requirements and preparation of thorough procedures and processes to enable success.”

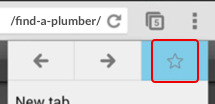

Local plumbing business and Master Plumbers member TJ Coles Plumbing (profiled on page 24) has also been involved in finalising the prototype demonstration model, which was showcased at a launch event attended by Victorian Minister for Energy and Resources, Lily D’Ambrosio. Ross told attendees that the demonstration shows “that the crematoria sector and mainstream industry more generally that green hydrogen can be easily, safely and quickly integrated into our respective operations with no business risk.”

Critical to the success of the project has been the support of the Australasian Cemeteries and Crematoria Association (ACCA), which Austeng has been involved with since the 1980s.

“ACCA as well as some other large crematoria organisations provided a letter of support, and the Geelong Cemeteries Trust was a supporting partner in the grant application and very encouraging throughout,” says Ross.

“The hydrogen blend step is just the first step towards the final aim of 100 per cent powered hydrogen cremations. We are exploring with some organisations to retrofit existing cremators with a natural gas and hydrogen blend as a step towards paving the way to the conversion of 100 per cent hydrogen in the future.”

Austeng is not aware of any other countries using hydrogen-fueled crematoria furnaces, and is already fielding enquiries from New Zealand, Europe and the UK.

As for the next steps, Austeng is looking to roll out its hydrogen-blend technology with existing crematoria customers, work with customers to establish green hydrogen supply chains and continue development on utilising increasingly larger hydrogen blends on the way to 100 per cent.

L-R Sam Welsh (MP), Aaron Bridger (MP), Peter Daly (MP CEO), Travis Coles (TJ Coles Plumbing), Michael Tomlinson (former MP Board), Gary Bath (MP)

“The potential is enormous and lessons from the project will be applicable to decarbonising other gas-fired industrial processes in the future.” Master Plumbers CEO, Peter Daly, who attended the showcase event with board members and staff says the plumbing industry has a key role to play in making the Victorian economy “hydrogen ready” and in supporting the safe installation and maintenance of appliances, like the cremator, which has been granted Type B gas appliance approval from Energy Safe Victoria.

Peter says that Master Plumbers has been anticipating the current shift towards hydrogen for some time. “That’s why our state-of-the-art PICAC training facilities in Brunswick and Narre Warren are being equipped with world-class hydrogen training equipment, including separate zones where training can structure towards hydrogen gas. In Queensland, PICAC has a purposebuilt, world-class Hydrogen Centre of Excellence to train or retrain practitioners to use blended or pure hydrogen safely.

We believe that Australia is well-placed to embrace and take advantage of the possibilities and opportunities provided by hydrogen, recognising that blanket electrification will not support all our energy needs in the foreseeable future.”

L-R Michael Tomlinson, Peter Daly, Minister Lily D’Ambrosio (Minister for Energy and Resources) and Ella George (Member for Lara)

Share this Article