Sifting through the compliance requirements is not easy when it comes to drain-bedding material. Here, Master Plumbers’ Senior Technical Advisor Gary Bath guides you through.

Recently, the Victorian regulator has had a strong focus on ensuring that the material used for bedding of the sanitary drain satisfies AS/NZS3500.2 requirements.

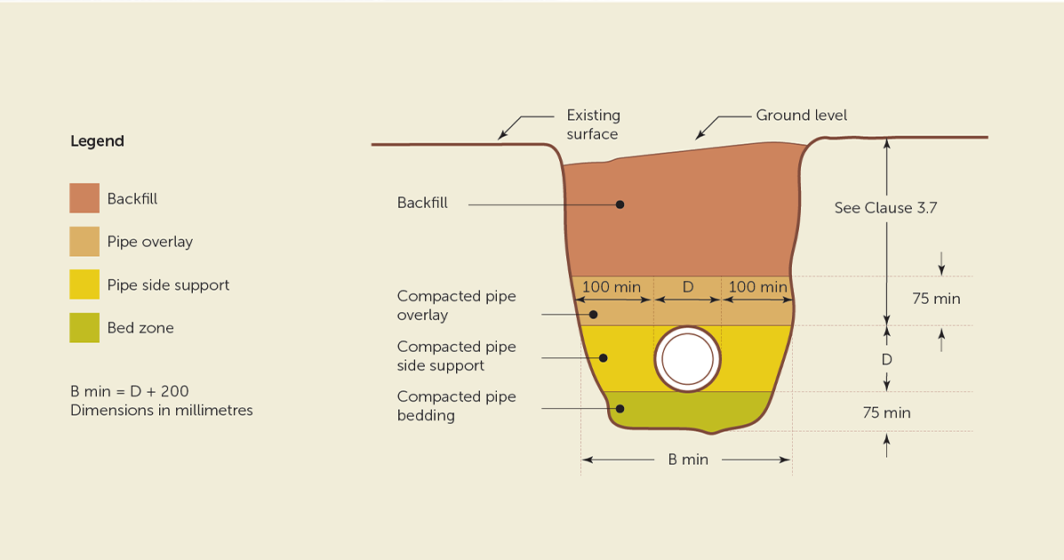

In general, external bedding material is required when the trench is over excavated or when the ground contains clay, rock, shale, gravel or hard objects that may damage the installed pipe. In stable ground, the drain can be put directly on the undisturbed base of the trench provided the base is free from rocks or tree roots.

Approved bedding materials are:

- Crushed rock, gravel screenings or similar recycled materials (eg roof tiles or bricks) of a nominal size of 7-10mm.

- Cement mortar containing 1 part Portland cement to 4 parts sand by volume, thoroughly mixed with clean water to a workable consistency.

- Cement mortar bedding where the base of the trench is rock or shale where the grade is greater than 20% (1 in 5), the cement mortar shall be:

– Of a minimum depth of 50mm, measured below the barrel of the pipe.

– Not less than 75mm wide.

– Not closer than 20mm to flexible joints.

– Have pipes supported at not greater than 1500mm from the centres, prior to placing the mortar bedding.

- Free running sand capable of passing through a 2mm mesh sieve, which does not contain clay, organic or any other deleterious materials.

So, what is the issue?

Historically, plumbers have used a bedding material that the industry knows as ¼ minus. In fact, pre-dating the current regulator when individual water or sewage authorities had responsibility for inspecting sanitary drains, there were some authorities that would insist on crusher dust or stone dust, which was a product that consisted of blue metal (4mm and less) sometimes described as fines.

The ¼ minus is a product that was generally blue metal or similar gravel that would pass through a ¼ inch sieve (6.35 mm) meaning that the product was 6.35mm down to fines in most cases.

The issue from the regulator’s perspective is that ¼ minus does not meet the DTS requirements of the AS/NZS3500.2 in that it is not 7-10mm gravel or similar neither is it “free-running sand” that could pass through a 2mm sieve.

On the subject of sand, being an acceptable bedding material, Victoria has a variation in the Plumbing Code of Australia, (NCC Vol 3) stating that sand may only be used as a bedding material if it is excavated from the trench.

Access to material that meets these specifications is another issue, locally sourced material and the quality of that material is a financial consideration, material is ordered and delivered to site by suppliers where quality control is the responsibility of the certifying drainer in most cases.

Where to from here?

There are current discussions with the Victorian regulator to achieve an outcome that will hopefully provide plumbers with sufficient information and technical guidance to ensure compliance with their interpretation of the Standard. Whether that is in the form of certification from the supplier of this material, technical direction from the VBA or whether it will be left to the installing plumber to cast a quality assurance eye over the material supplied is yet to be seen. Our historical use of ¼ minus screenings makes this focus on bedding material all the more baffling given we don’t have any evidence where these drains, laid in ¼ minus have failed as a result of this material choice.

Share this Article