Sam Welsh, Master Plumbers Technical Adviser, debunks the requirements around inspection openings.

Some in the plumbing fraternity have suffered from misconceptions over the correct placement of test and inspection openings in sanitary plumbing and drainage systems.

What is a test opening?

Test openings are defined as an opening with a removable cover in the body of a fitting and of sufficient size to permit the installation of a plug for use in the test procedure.

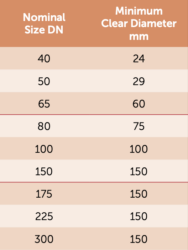

Note: be aware that when a test opening is being installed it must be installed with the correct clear diameter. See table below.

What is an inspection opening?

Inspection openings are defined as access openings in a pipe or pipe fitting, arranged to facilitate inspection testing or the cleaning of obstructions, and are fitted with a threaded cap, plug or access cover drain. They are a vital and very useful part of any sanitary plumbing and drainage system because when installed in the correct locations, they allow access to the drain for servicing and maintenance.

Where are they required?

(see Figure 1). One of the biggest misunderstandings comes from Clause 4.7.1 of the AS/3500.2 -2021 where it discusses changes in direction greater than 45°. Many believe this applies in Australia however, this clause applies in

Other locations where inspection openings are required according to AS/NZS 3500.2-2021 clause 4.7.1 include:

a) Outside of a building, not further than 2.5 meters along each branch drain connecting one

or more water closets or slop hoppers;

b) At intervals of no more than

30 meters apart, with a minimum of one inspection opening on each main drain;

c) At the connection to the network utility operator’s sewer if one has not been provided by the network utility operator;

d) On the downstream end of the drain where any drain passes under a building except where waste fixtures only are concerned;

e) Where any new section of drain is connected to an existing drain; and

f) Immediatelyatorupstreamof the upper bend of a jump up. (The standard defines a jump-up as a section of a drain joining two sections of a horizontal drain at different levels. The locations listed require inspection openings unless inspection chambers are provided.)

New Zealand only:

Clause 4.7.1.

g) at every change in horizontal direction of greater than 45° (New Zealand only)

h) at every change in gradient greater than 45° (New Zealand only)

Note definitions:

- Waste fixture

A fixture other than a soil fixture

- Soil fixture

A fixture used to discharge excrement and similar waste

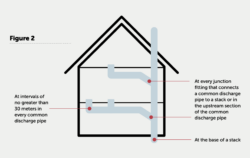

Further to the below-ground requirements, sanitary drainage systems require test and inspection openings in various locations also (see Figure 2). All common discharge pipes and stacks shall be provided with openings for inspection and testing in the following locations:

a) In any common discharge pipe where necessary for inspection and testing;

b) At the base of every stack;

c) At any level of a stack where necessary for inspection and testing;

d) At intervals not greater than 30 meters in every common discharge pipe; and

e) At every junction fitting that connects a common discharge pipe to a stack or in the upstream section of the common discharge pipe.

Further information can be found under clause 10.5.2 of AS/NZS 3500.2-2021.

Share this Article