With almost 45 years in the sanitaryware design industry, Dr. Steve Cummings is an authority when it comes to product innovation. A respected figure both Internationally and at home, Dr. Cummings is a pioneer in sustainable design and research, dedicating his career to developing products that minimise water consumption.

In this episode, Dr. Cummings shares his experiences from four decades in the sanitaryware design industry, his passion for innovation in design and the latest product from Caroma, Smart Command.

Transcript

Daniel: Welcome to another episode of Master Plumbers Radio. I’m your host, Daniel Carroll, and today I’m joined by a guest who’s highly respected amongst the Australian industrial design community, Dr. Steve Cummings. He’s a renowned industrial designer and fellow of The Design Institute of Australia. He was inducted into the Design Institute of Australia’s Hall of Fame in 2012, and since has held senior appointments in the bathroom product design industry and has had a longstanding participation in standards development in Australia and internationally since 1981. A pioneer in sustainable design and research, Dr. Cummings has dedicated himself to developing products that minimize water consumption. He’s recognized internationally as an authority in this field, is an associate of the Institute of Sustainable Futures, and collaborates in Australia and internationally with universities, industry experts, governments and standards representatives. Steve, thanks for joining us on the show today.

Steve: Good to be with you, Daniel.

Daniel: You’ve been involved in design for more than 40 years. How did it all start? Where’d you get your start in the industry?

Steve: I started in the industry in 1976 where I joined Doulton Australia in designing sanitaryware. I became chief designer there before I moved on to Caroma, who took over Doulton.

Daniel: As someone that is interested in design myself, I can’t imagine being a designer in a world where there’s no computers to help out with what you’re doing. Tell us about what it was like in the early days of being a designer with so much of the technology we take for granted now not being available.

Steve: In the early days, it was more sketching and communication through sketching and drawings. When I look back, we had drawing boards, we had a whole team of people working on drawing boards. There was no such thing as mobile phones or computers when we first started.

Daniel: No email, so I can imagine that communication would have been a bit tough.

Steve: No emails. Well remember the telexes used to come in over night, so that was the communication with outside world, apart from the telephone. It was interesting, we made do then, but it’s far more sophisticated and productive now than it used to be then.

Daniel: Tell us about some of the early projects you were involved with.

Steve: Well, some of the key projects that I worked on early was just developing toilets, making them more consumer friendly. When I got there, the products were pretty basic, the basic toilet pan with an exposed trap. We had some movement to concealed traps at that time, that was in the ’70s, and I started to develop products, then, that concealed the trap, made it look better, easy to clean, which really evolved right into what we’ve got now.

Daniel: So, as I touched on before, there’s no doubt been significant development in the time since you started. What would be some of the challenges that you’ve faced in that time from when you started going along your career?

Steve: I think, when I started my expectations of what we should be doing was limited by our capability of doing it, and that was in manufacturing. So, concurrently with the development of what we were doing, we were then increasing our capacity to develop the products that made us competitive internationally.

Daniel: Your current position at a Caroma or GWA is Innovation Director, and just speaking earlier, you’ve always specialized and focused on innovation. What does innovation as a concept mean to you?

Steve: Innovation, to me, is something that’s new, hasn’t been done before. You can get variations on product design, but it’s something where you can get IP so you’ve got something that can protect that innovation, and it’s seen as new in the marketplace as well.

Daniel: Okay. You’ve been with GWA for 38 years now, how do you maintain your drive over such a long span? What’s your secret?

Steve: Well, I think the changing projects and technology as we move into different areas, I think that’s always a challenge, it’s a learning process for me and the team. I think that keeps me going, and being able to make steps up the ladder as far as what you’re doing is very important and that keeps me going. It keeps me mentally alert.

Daniel: Yeah, okay. In the early 2000s, you received a doctorate in Environmental Design from the University of Canberra. I’m going to assume that many of the people out there would not understand the significance of design, just in the environment around us, to the point where most of us would probably take it for granted. Are you able to share a little bit about the importance of good design and how it influences the majority of what we experience in life?

Steve: If I go back to the work we did originally on dual flush, in the early ’80s when we released it, we were flushing with 11 litres for the full flush at that time. We made it dual flush, which made 11 five and a half. Then, I went on a journey where, that was for the cistern, where we started to look at the toilet pans and what we could do there. The limitation on the performance of the cistern was the pan. You had the cistern that can drop the water, but you had to actually do things in the pan, so once you to start reducing the water going into the pan, then you had to really look at the pan design. In 1993, we released the 6/3, which was a total redesign of the pan and cistern.

Daniel: So you essentially halve the water use just in one go.

Steve: Just in one go, and it was only because we could change the pan. When we changed the pan, we also started to get very interested in the water utilities, and very interested in the drainage system that we married it up with. Then, I formed alliances with the leaders in water conservation with the utilities, where we started to do developments, and then I got very interested in the research, particularly in drainline research and what happens with the waste in the drainlines, which is vital. You just can’t design a project and put it on a system. While it might clear the waste, but it doesn’t work within the drainline system, so that is not a good design.

Steve: From there, from 1993, we did further research, until 2004 where we developed the 4.5/3L flushing system. Again, a lot of work with the drainlines, a lot of work with field trials, extensive field trials across Australia, where we validated the system. That required us to get to the next stage in the development of the pan, it was all to do with the pan, where we minimized all the critical areas of where the water was running; how to make it more effective and flush the waste out of the sump of the pan into the drainline system, through the drainline system into the main sewer system, and without blockages.

Daniel: So you’re essentially starting with six two-litre milks of water entering the cistern. Of course, that would cause the design of the cistern to be a certain shape and size. When you’re coming to realize the new solution for what you’re trying to do, are you already looking for the next… or where it can go after that? You’re essentially halving it in your first stage of the project, are you already looking to see how much further you can reduce the water use, or is it sort of mainly focused around that one project for a little bit of time?

Steve: You’re always looking to the future, but when you do these things that you’re being an innovator, you have to make calls. Going back to the 6/3 cistern we developed, we had big tanks, and you probably see them around, they’re still around, not too many of them, big tanks with 11 litres of water in them. When we moved to 6/3, we were able to reduce the volume by… well, reduced the visual part of the cistern by half, virtually. Which is a big shock to those that were used to looking at big cisterns all the time, so we had a market thing at the time to deal with that. While some were concerned about it, we took the risk and did that. It was a massive risk for us to change all our tooling to cisterns that were half the size without much market knowledge of how they were going to go, but going from early resistance to market acceptance was a 12-months process. If you looked at the big ones now, you would never put them in, but at the time there was some that thought, “No, they’re not too bad.”

Daniel: Yeah. Just thinking about the reduction in size, there’s been a big boom in renovations with The Block and all those shows on TV. Everything’s about aesthetics these days, everything has to look nice, no one wants… You use your bathroom quite a lot, no one wants to be walking into something that looks quite ugly and space is a premium in many homes these days. So, just thinking about the advantages of being able to reduce the cistern by half, we see the ability to have things like the cisterns that are built into the wall these days and saves a little bit more space. Going back to my point before about people taking design for granted, it just happens. But it doesn’t, there’s people behind the scenes like yourself that are thinking about ways we can do things better so, in the end, everyone benefits.

Steve: Yeah, I hope so. We put the effort into it. That’s the aim of what we’re doing. Yeah. You mentioned in-wall cisterns, we completely redid our in-wall cistern around the time that we changed to 4.5/3. Then, we were able to consolidate the cistern size and the performance then, where we came up with the whole, totally-new in-wall cistern. We worked very closely with plumbers on that because it’s not a easy thing to install, in-wall cistern. So, we worked very closely with the plumbers, and we came up with the Invisi II cistern.

Daniel: You’re probably working on another project now to reduce that even further, can you let us in any secrets on where it’s headed or what we can expect to happen there?

Steve: I’ll just say, there’s always room to be more efficient, but one thing that you’ve got to do is make sure that, as I said before, it doesn’t adversely affect the current system. So any change, you’d have to do the research.

Daniel: I’ve read online about the constant challenge of what we’ve been talking about now, to develop new product concepts that are at the forefront of industry, and on a global scale. The dual-flush toilet’s a great example of this evolutionary production. Can you share some of the experience in designing and developing a product that’s constantly evolving? We just spoke about how you’re constantly looking to make it better and drive efficiencies, where do you find your inspiration, I guess, to drive these solutions? I guess there’s a lot of science and mathematics behind it, do you have to go and research internationally to see what people are doing differently or does all of that thinking come locally?

Steve: The thinking comes locally, but it’s influenced by what’s going on overseas. The latest evolution of the toilet pan, for us, was the Cleanflush where we eliminated the rim with the cistern to make it easier to clean, and we did a lot of work on the flushing technology around that to make sure that we didn’t lose the efficiency. We saw the trend coming from overseas, in Europe mainly, then we looked at what we could do to make it fit with our system and provide the flushing performance that was to be expected. We didn’t want to reduce the flushing performance of the product, so we spent as considerable amount of time in researching and getting the system operating correctly so that it gives us the similar flush performance to what we’ve been used to.

Daniel: I’ve seen a few videos online about how the Cleanflush system works, and would I be right in saying that the difference between the evolution of the two systems is that the latest one has the different shape of the pan so it projects the water in a certain way to make up for… I’m probably getting jumbled in my science terminology now, but the shape of the pan contributes to the pressure of the water eliminating the waste? Is that right?

Steve: Yeah. When we started looking at the rimless technology, it’s critical… With that, and I switch back to what we did with the 4.5/3 Development, we knew that if you’ve only got a small volume of water to use, there was no room for error with 4.5/3. So, if it moved away and didn’t hit in the right place, then there’s no more water coming behind that, you’ve missed it, so it’s not going to perform well. So what we looked at when we started doing our early flushing trials with rimless technology, we noticed that because you didn’t have a closed rim that guides the water around the bowl, the water would swing from side to side. That didn’t give you the accuracy of flush that you needed to perform as required for a 4.5/3 system, the effective flush. It was a lazy sort of flush. Also, being able to control that was up to the production process because there was punching of holes in the back of the pan.

Steve: So how did we get around that? We did a lot of work and a lot of testing. That’s when we formed that splitter of the front front of the pan where we divided the flush. So we thought, well, we’d stop the water… we’d just stop it with that so the water would run around and both would meet in the center. That sounds easy, but it wasn’t. We did hundreds of different iterations of that to get at just right so it gives you a very similar flushing performance, if not better, than the rim type, which is a major achievement for us. Whereas others didn’t go to that extent where flushing and water conservation is really part of what we do, and we wanted to make sure that what we came up with reflected that.

Daniel: It’s interesting to hear the amount of work that goes into something that many people would consider so simple and take for granted like the flush of a toilet. I’m sure that’s type of effort and development goes into a lot of other products, are you able to tell us about some of the other things that you’ve worked on?

Steve: Obviously, with a toilet, for men, you’ve got a urinal, so a lot of satisfaction out of working on urinals, as well, and being able to reduce the flushing volume of a urinal down to 0.8 in a Cube from the standard 2. So, pretty significant reductions in water usage there. Not the same as what we’ve got out of the toilet, but I’ve got a passion for urinal design, and they’re quite complex when you start looking at them closely, like I do.

Daniel: Okay. We talked earlier about some of the work you’ve done in disability care or aged care.

Steve: Yeah. I look at it, the water conservation side of what I’ve been involved with, with a team. The other part was a dedication to making our bathroom products better for disabled people and aged people to use, where they’ve got some sort of disability, and also people that are rehabilitating from an injury. I started very early with that, and I did the first raised pan. The old days, the plumbers used to just build the pan up, with a cement bed, off the ground. Looked terrible. That was the start of, “Okay, well, how can we make that better?” So we just built the pan to be installed normally but provide the raised height that was required by the standard. Then I got involved in the standards for that as well.

Daniel: Okay. Touching on the standards, the quality of the items that we use in the construction industry is always in focus, and more so in plumbing over the last few years with the introduction of the WaterMark scheme in Australia. I believe you were part of the group that was responsible for the implementation of that scheme. How important is it that a scheme like this exists?

Steve: Well, I think for products that can affect the public health and safety of Australians, it really needs to be regulated and come under a scheme like the WaterMark scheme. Other major economies around the world have got regulation to varying extent, some are highly regulated, some are not so much, but I think it’s just fundamental for the industry that we’ve got a product that we can trust in with the WaterMark name on it. We know that it’s been tested and developed correctly and is meeting the requirements for Australia.

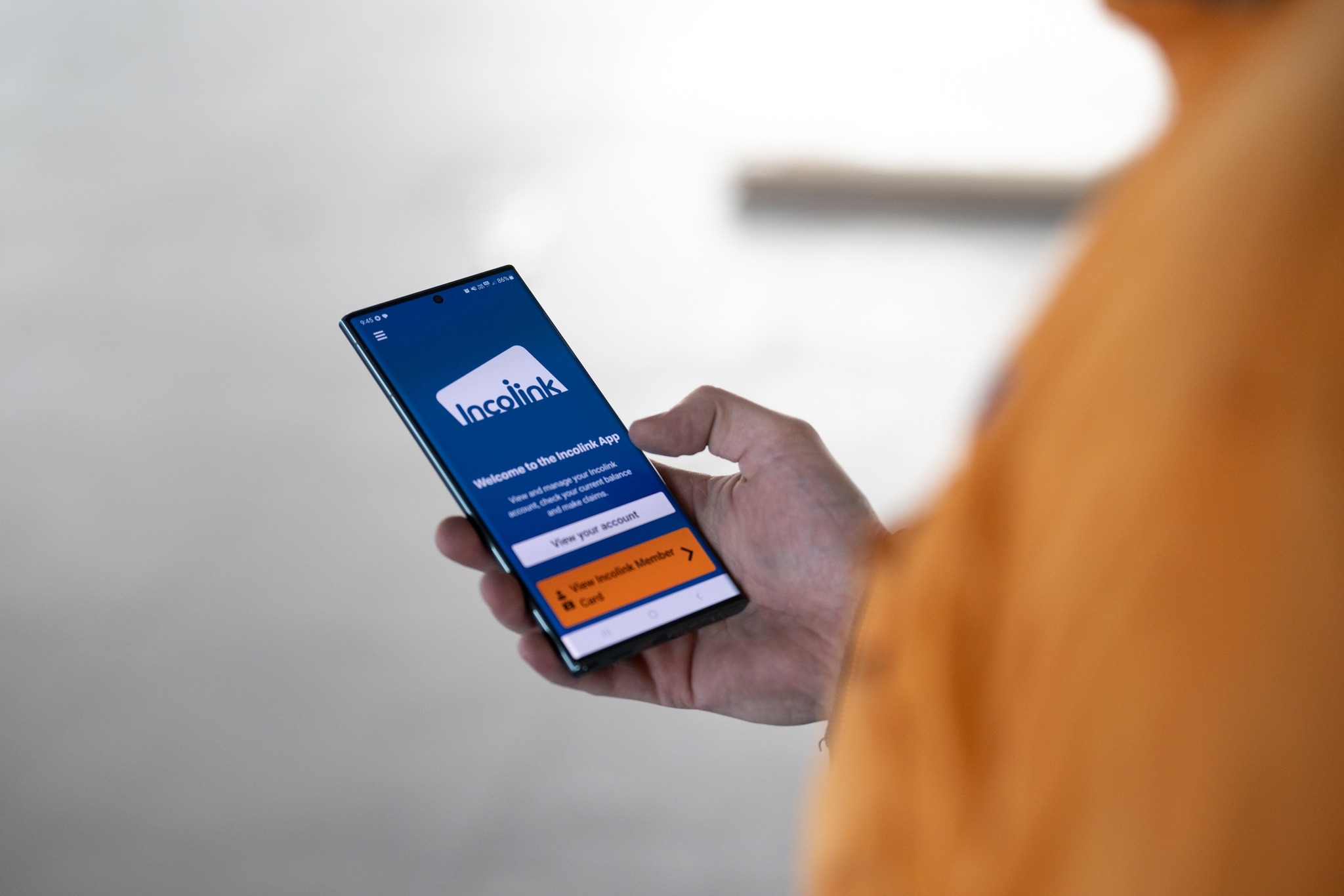

Daniel: Earlier in the year, I attended the launch of the Smart Command product, a Caroma product that’s described as “an ecosystem of intelligent products that enable building managers to monitor water use in real-time and make smarter decisions that reduce maintenance costs, while improving hygiene and up time.” Can you tell us a bit about how that project came about and how it works?

Steve: Sure. It was around around six years ago, down here in Melbourne. We had a maintenance issue on a project, a key project in Melbourne, and I was working with a hydraulic engineer on it just to see where the issues were. What it required us to do was take urinals off the wall and, in a building where you’ve got a lot of them, it’s not a great job. When you take it off, you’ve got urine… And plumbers would know this, you get sewer gas, water and urine on the floor, close the bathrooms off as you’re doing the work. Not pleasant and very time consuming. What we were trying to do is verify what the flushing volumes were that were set up in the urinals. The only way we could do that, it was pull them off the wall, connect the hose to the inlet, and then dummy up the flushing system so that we could flush it and measure the water in a bucket. To do that through a building was really crazy, and we both looked at each other and said, “Well, there must be a better way to do it.”

Steve: Then, I started exploring, “Well, where can we do that? Can we use a light or a buzzer that indicates something’s not working correctly?” Went back and tried to get that done. No, couldn’t do it. We’d have to redesign the electronics. That was the start. We started looking at the electronics and what we had to do. Then, we came up with a urinal that you could communicate with using a smartphone. That was the first of the… and at the time when we doing it, six, seven years ago, it was a really new thing. It was IOT product and, at that time, what IOT product was was, “What is that?”

Daniel: Yeah, and for the people listening at home, the IOT, the internet of things, which is, I guess, going to be even more relevant in the future of whatever we do, the way people become more connected is through the internet of things and it just means being able to use the internet to connect with whatever you’re using or consuming, I guess.

On that, as the world continues to accelerate into the future, there’s talk of smart cities and the technological revolution that implements, as we said, the internet of things. What does the future hold, do you think, in the plumbing industry and the design of products?

Steve: I’m a believer of using the gravity to flush the system and operate the systems. Vacuum systems have got their place and they’ll be used in varying areas where there’s issues, but I think, overall, the system will remain gravity. Maybe assisted by some special technologies that will come. I see the digitalization of the plumbing industry is going to be widespread. We’re going to get a lot of data coming from coming from the sensors that we’ll be using throughout the plumbing system. From the data, we’ll be able to make valuable decisions on things that we don’t know about now, which is exciting, I think.

Steve: I think, as you mentioned before, it’ll be IOT led, so you’ll have products that talk to each other, you’ll have products that talk to the user, you’ll be able to direct products, you’ll be able to direct cleaning, you’ll be able to direct maintenance from a plumbing site. There’s a whole realm things that we haven’t been able to do before. It’ll make it so much more efficient, so much more effective from the plumbing side, particularly, where you know what’s going on, you don’t have to go and troubleshoot something. You’ll be told, “This is the issue,” and you’ll be able to fix it directly rather than investigating it and pulling things off the walls like I was doing with the urinals. It’s a lot smarter way of doing things. It makes the job better rather than having to do the bad side of the maintenance.

Daniel: Just going back to the Smart Command product for a little bit, is there anything else you could tell us about how it works and why it’s going to be a valuable introduction into any commercial building around the country?

Steve: Going back to the urinal, when we developed the urinal to communicate back to the user using your iPhone or…

Daniel: Tablet or whatever.

Steve: Tablet, whatever. We then thought, “Well, okay, we’ve got this… ” It was really good stuff, but we thought, “Okay, well, why don’t we extend that to the whole commercial bathroom?” because this is where it was born. So, we looked at the Invisi toilet, and we came up with a system of making that IOT and communicate back into the iPhone. We looked at the basin, the tapware on the basin, and making that smart and IOT. Then we had the basis of a bathroom system.

Steve: Then, we set out working on that. We released it last year, those three products. We’ve now moved on to others like a shut-off valve and smart shower. All communicate back, you know exactly how much water each product’s using, it’s coming through onto a building management system. So, while we still use the smartphone or the tablet to set the products up, then they now are talking to a gateway that’s in the bathroom. So, that’s wirelessly talking through Bluetooth to the gateway. Then, from the gateway, that’s communicating to a concentrator, every bathroom’s gateway that communicates with the concentrator, and that concentrated then feeds into a building management system and/or the Caroma cloud that we’ve developed to service this if the building hasn’t got a building management system or if the building manager wants to use our cloud, then that’s available.

Steve: So you’ve got a total system now, whereas we were only having iPhone communication, then we broadened it out so it’s whole-of-building. So the whole-of-building you can control, you can control the flush volumes for some products remotely through the building manager. You can just put in what the value is and send that through, and you can change all the flush volumes throughout the building.

Daniel: Wow. I believe, one of the biggest things I took out of that demonstration a few months back now was that it’s got a really big impact on maintenance, as well.

Steve: Yeah, yeah. It was born through a maintenance issue. So yeah, when we did the urinal, we wanted to know what the volume was, how the product was functioning, whether there was any issues with the solenoid valve. All this was communicated back to you on your iPhone or the building manager. So anything that affects the product’s performance, the key thing’s we’ve got the urinal would come back to us to tell us what the issues are.

Daniel: In regard to maintenance, with a system like that, is it possible to sort of pinpoint, “Okay, we’ve got a blockage in a pipe on the third floor and in room whatever?” Does it have that level of knowledge within the system to be able to…

Steve: We’re moving there, but at this point in time we’re only talking about the products. But even on the product, if you’ve got a… like with urinal, if there was a problem with the solenoid valve that operates the urinal, then that would go… it could go back, via the building management system, to the plumber and tell the plumber, “On Level 6, urinal 3, there’s a issue with the solenoid valve.” Then, the plumber then could go to the plumbing merchant and buy the part, go directly to the urinal, change it, and get it right the first time rather than go back, check it, then go back, maybe get the wrong part then have to go back, backwards and forwards, which is really inefficient. They become more more efficient, be able to do more work, and offer the customers, the building managers, a great service where they can identify and solve problems fast.

Daniel: Great. Before we started the recording today, we had a little bit of a chat about CPD. I explained about how Master Plumbers is trying to introduce a CPD program to its members and the wider plumbing community to help sort of keep up to speed with what’s happening in the industry and keep yourself fresh. I can imagine something like that, up to a certain point, would become pretty valuable to you. What sort of things were you looking at to keep your knowledge of what you were doing up to speed and just sort of maintaining your position as a thought leader in the industry?

Steve: Well, I’m regularly going overseas to industry exhibitions, conferences, and talking to overseas suppliers that have got knowledge of the developments that are in place internationally. So I think I’m right up to speed with what’s happening internationally. Don’t underestimate the work that we’re doing in Australia, either. It’s internationally competitive, and I think we’re in the forefront as well. If I look at Smart Command, for example, I went to a light and building exhibition in Frankfurt, in Germany, a number of years ago where I looked at the building management direction, so I saw how they saw the building management systems of the future. Then, I came back and applied that model to what we were doing. I’ve been back since, and we’re exactly where they’re going with the cloud-based system that I talked about before. That influenced me greatly and I’m constantly doing that. I’m looking for opportunities, what can we do, how can we be better, how can we be as good as them or better, rather than when I first started going, where they were so far in front of us in the ’70s and ’80s, it wasn’t funny.

Daniel: Yeah. I’m going to take a guess and say that’s sort of changed over the years. Do you find people, in an international level, coming back to Australia to see what we’re doing and sort of using the knowledge of the people here to influence what they’re doing abroad?

Steve: I see, because I’m talking to them, the international suppliers, and I think we’ve got a respect in Australia for what we do. There’s a quality element of how we look at things, we like things to perform well and be able to be serviced well. That’s general across the industry, I think the good guys in the industry are really making great products, and I think that’s taken up by the suppliers because they know that it’s difficult to come in with products that aren’t competitive to the products available here.

Daniel: Okay. Speaking of an international audience, you’re scheduled to speak at the World Plumbing Conference later in the year in September. Can you tell us a little bit about what we can expect to hear from yourself in the conference?

Steve: Well, it’s going to be around Smart Command. I think I’ll drill down a little bit more into the detail of Smart Command and what it can do, but I think this is a good introduction to what I’ll be talking about in the conference. That’ll be Smart Command.

Daniel: Is there anything in particular that you’re looking to get out of being a visitor to the conference?

Daniel: There’s always things I want to get out of it. I think association with our overseas visitors. I’ve been contacted by colleagues in Switzerland and around the world, US particularly, where they’re coming, they’re going to present as well, some of them. I think it’s a coming together of all the experts in plumbing from around the world, which I think it’ll be a fantastic thing for all of us when we get there.

Daniel: Fantastic. Dr. Cummings, thank you very much for joining us on the show.

Steve: It’s been my pleasure, Daniel. Thank you.

Share this Article